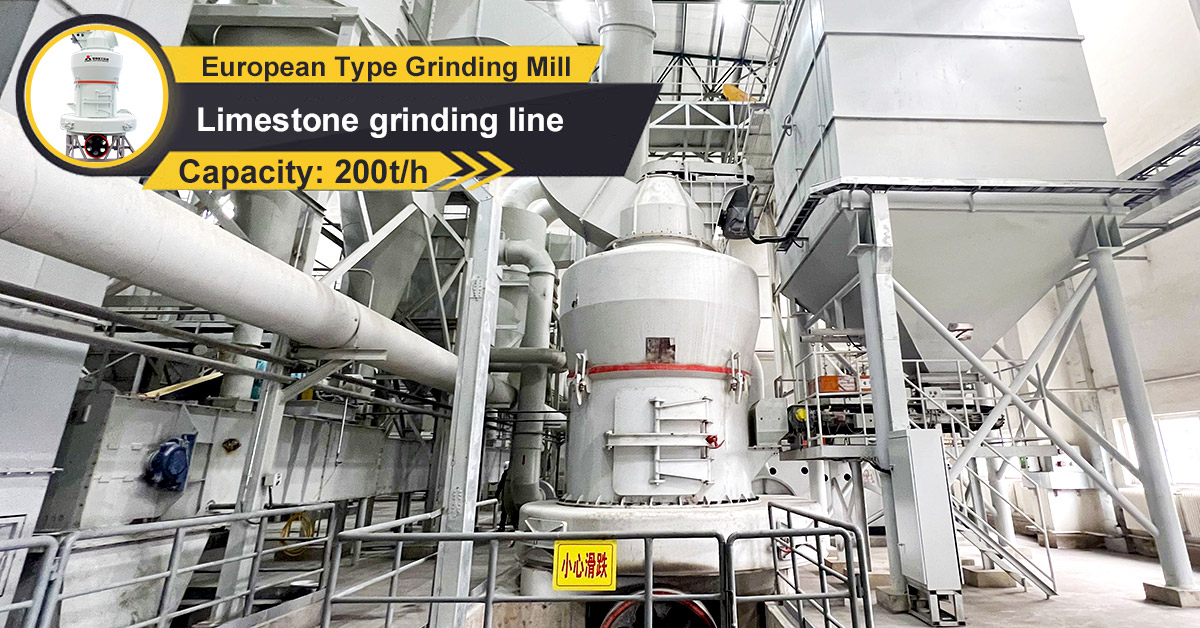

325 mesh limestone powder production line

Phase one: raw material crushing limestone blocks will be crushed to 15mm-50mm fineness by crusher.

Phase two: grinding limestone material will be sent to the storage hopper by the elevator, and than the feeder will send the material to the main mill for grinding.

Phase three: classifying ground material will be classified, coarse powder will fall back to the main mill to be ground again.

Phase four: production collecting qualified powder will flow with the air and be collected in the collector, then the finished powder will be transported to the product storage bin through discharge port. Lastly, the powder will be loaded by tank car or packed by packing machine.

If you are interested in the limestone powder production line, click on our online services for a detailed consultation.

CAS

-

>

Ligne de production de poudre à partir de scories de révision d'aluminium électrolytique

-

>

Projet de préparation du charbon pulvérisé pour haut fourneau

-

>

Broyeur à charbon 25TPH

-

>

Ligne de production de ciment silicaté

-

>

Broyeur vertical LM27-3N, traitement des scories, 325 mesh, 6 t/h

-

>

Broyeur à boulets LM35-3N

-

>

Projet de préparation de poudre GBFS

-

>

Préparation de poudre de sable calcaire

-

>

Broyeur vertical LM19-2N, traitement des scories, 10-15 t/h

-

>

Ligne de production de ciment avec broyeur à boulets 20-25 t/h

En savoir plus

Chat en ligne

Chat en ligne

Laisser un message

Laisser un message